With 10-plus years experience operating several PVD machines on site using both Sputtering and Arc techniques alongside a full range of electroplating configurations we are confident we can service all your PVD & Plating needs. Contact one of our PVD & Electroplating specialists today for a service quote to begin your effortless COATING journey.

1. ISO 9001:2015

2. ISO 14001:2015

3. OHSAS 18001:2007

4. The Sedex Members Ethical Trade Audit (SMETA)

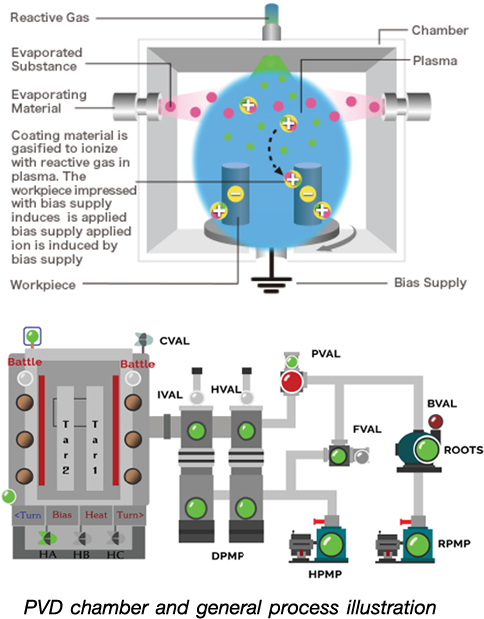

PVD (Physical Vapor Deposition) is a vacuum coating process of vaporizing a solid metal to plasma of atoms or molecules, vapor that can be deposited as a high performance coating on wide variety of substrates. Evaporation in PVD can be forced by several methods. At Salamander Jewelry we use these two methods:

1. Magnetron Sputtering, where the coating material is "blasted" from the target by plasma.

2. Cathodic Arc Technology in which an electric arc is used to vaporize material from a cathode target. The high concentration of ions allows control of film morphology, high adhesion (none other methods can provide), efficient reactive deposition of compounds and uniform deposition over a variety of shapes.

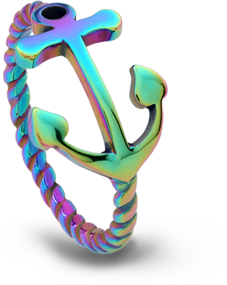

Mixing high purity gases used during the process we obtain specific colors combining the benefits of a decorative finish with excellent wear and corrosion resistance. This thin film provides a protective skin on the jewelry enhancing the visual and functional performance.

PVD will not dull and it will not level or fill like an electroplated finish so the surface design will still be visible after the coating process.

In PVD, the substrate does not need to be metallic or electrically conductive, making it possible to coat ceramic and plastic objects..

The use of PVD is increasing rapidly in the industry to replace chemical and galvanic methods. PVD coating benefits are many.

- Will not Chip, Tarnish or Fade.

- Superior Wear Resistance.

- Superior Corrosion Resistance.

- Superior Chemical Resistance.

- Excellent Adhesion and Coating Quality.

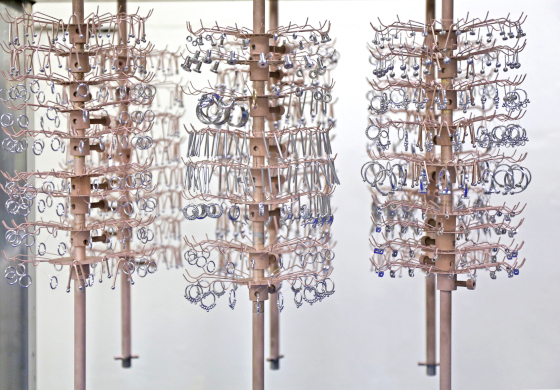

- Accurate and even distribution of coating.

- Clean and dry environmentally friendly process, with no hazardous materials involved and does not generate chemical waste or water pollution.

- Lower overall cost over time compared to traditional plating.

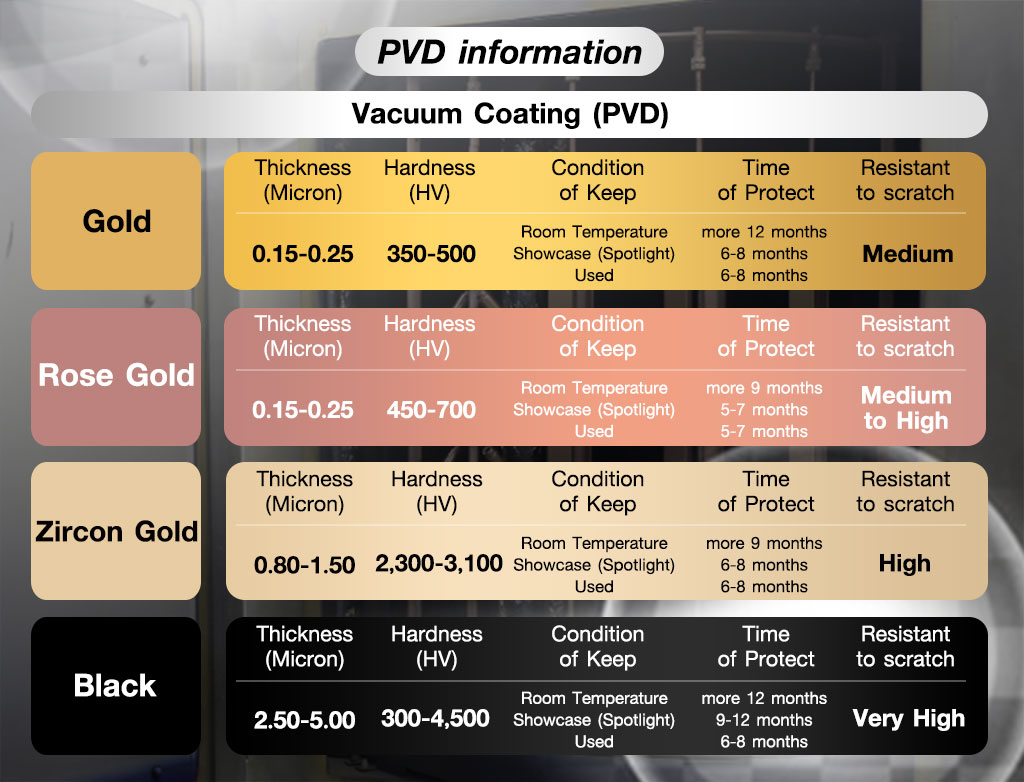

As the machines and parts are expensive and require constant maintenance and extensive operational knowledge, many manufacturers and suppliers do not offer such services. We owns 3 such machines and offers a wide range of high quality materials in various color. PVD information